UV Surface Disinfection Made Simple: Carrying Out Finest Practices for Optimal Outcomes

UV Surface Disinfection Made Simple: Carrying Out Finest Practices for Optimal Outcomes

Blog Article

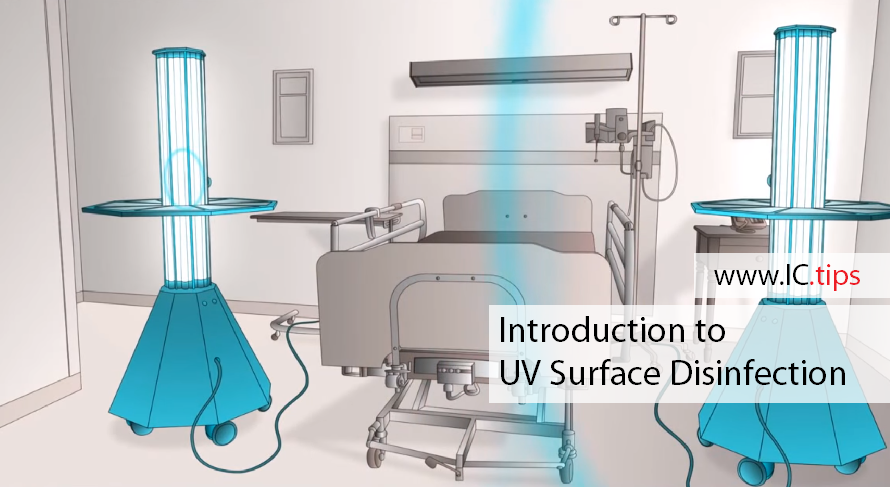

UV Disinfection: The Cutting-Edge Innovation Transforming Sanitation Practices

In the realm of cleanliness practices, one innovation has emerged as a game-changer: UV disinfection. From health care setups to food processing, UV sanitation is making its mark in numerous industries.

How UV Disinfection Functions

UV sanitation works by using ultraviolet light to destroy or inactivate microbes, giving a chemical-free and very efficient technique of sanitation. This technology harnesses the power of short-wavelength UV-C light, which can harming the DNA and RNA of bacteria, therefore making them unable to reproduce and cause injury.

The procedure begins with the installment of UV disinfection systems, which include UV lights that produce UV-C light. These lights are strategically positioned in locations where microbial contamination is a problem, such as water treatment plants, health centers, labs, and food handling facilities.

When microorganisms are subjected to UV-C light, the photons penetrate their cell walls and reach the DNA and RNA inside. The high-energy UV-C photons interrupt the hereditary material by creating bonds between surrounding nucleotides, leading to the formation of thymine dimers. These dimers prevent the microorganisms from duplicating, rendering them harmless.

UV sanitation is extremely effective against a variety of microorganisms, consisting of bloodsuckers, viruses, and bacteria. It is particularly reliable against waterborne virus like E. coli, Giardia, and Cryptosporidium. UV sanitation is a chemical-free technique, removing the requirement for possibly hazardous disinfectants and lowering the danger of dangerous sanitation byproducts.

Advantages of UV Disinfection

UV disinfection offers various advantages in the field of hygiene, making it an extremely chosen method for efficiently eliminating harmful microorganisms. One of the essential advantages of UV sanitation is its ability to provide a chemical-free solution. Unlike standard sanitation approaches that depend on chemicals, UV disinfection uses ultraviolet light to ruin the DNA of microbes, making them not able to recreate and trigger infections. This not only removes the need for potentially damaging chemicals however also reduces the danger of chemical residue on surface areas.

UV sanitation is likewise highly functional in its applications. It can be made use of in different setups, including health centers, colleges, food processing facilities, and water therapy plants. UV disinfection systems can be quickly incorporated into existing cleanliness practices, offering an added layer of protection against infectious conditions.

Along with its performance and convenience, UV disinfection is likewise eco friendly. It does not create any kind of hazardous by-products or residues, making it a secure and lasting approach for cleanliness - uv surface disinfection. Additionally, UV sanitation needs marginal maintenance and has a lengthy life expectancy, resulting in price savings in the future.

UV Sanitation in Healthcare Setups

In healthcare settings, UV disinfection has arised as a cutting-edge approach for successfully removing damaging bacteria. UV sanitation works by emitting ultraviolet light at a specific wavelength that is deadly to germs, infections, and various other microbes.

To start with, UV sanitation is a non-chemical technique, making it an eco-friendly choice compared to standard sanitation approaches that frequently involve making use of severe chemicals. Using UV light removes the requirement for chemical disinfectants, reducing the risk of damaging residue or chemical direct exposure to both people and healthcare employees.

Additionally, UV sanitation is very reliable in killing a large range of bacteria, consisting of drug-resistant bacteria such as MRSA and C. difficile. It offers a reputable and consistent disinfection process, guaranteeing that all surfaces and tools are extensively sanitized, also in hard-to-reach areas.

UV Disinfection in Food Handling

The application of UV sanitation expands past health care settings and locates significant value in the world of food processing. uv surface disinfection. UV disinfection technology is ending up being progressively prominent in the food sector as a result of its ability to successfully eliminate unsafe virus and enhance food security

Among the main benefits of UV disinfection in food processing is its capacity to target a vast range of microbes, including mold and mildews, viruses, and bacteria. By utilizing UV light at specific wavelengths, it is feasible to interrupt the DNA and RNA of these microorganisms, providing them unable to cause or recreate injury. This technology can be put on various stages of the food handling chain, including surface sanitation, tools sanitation, and water treatment.

UV disinfection gives a chemical-free and non-thermal technique of sanitizing foodstuff. Unlike typical disinfection approaches important link that count on chemicals or warm, UV technology does not leave any residue or change the preference, structure, or nutritional worth of the food. This makes it an optimal option for industries that call for strict adherence to top quality requirements.

In addition, UV disinfection systems are very easy to install and run, calling for very little maintenance. They can be incorporated into existing processing sites lines without creating significant disturbances to the production process. In addition, UV systems have a quick treatment time, enabling continuous handling and reducing downtime.

The Future of UV Disinfection

One area where UV sanitation is anticipated to make considerable improvements remains in the area of medical care. With the rise of antibiotic-resistant germs and the requirement for extra reliable disinfection methods, UV light has the potential to play an essential function in decreasing healthcare-associated infections. UV disinfection systems can be utilized to decontaminate surfaces, devices, and also the air in health care centers, assisting to stop the spread of dangerous pathogens and boost client security.

One more industry that might gain from improvements in UV disinfection innovation is the food market. UV light has already confirmed to be a reliable method for decontaminating food items and minimizing the danger of foodborne illnesses. As modern technology boosts, we can anticipate to see much more cost-efficient and effective UV disinfection systems being implemented in food processing plants, making sure that the food we take in is secure and without damaging microorganisms.

Final Thought

In verdict, UV sanitation is an advanced innovation that is transforming sanitation techniques in medical care setups and food handling. By utilizing UV light to eliminate or shut down microbes, it provides many advantages such as safety, efficiency, and performance. With continuous advancements in this area, UV sanitation holds wonderful potential for the future of sanitation, offering a sustainable and trustworthy service for keeping tidy and sanitary settings.

UV disinfection is a chemical-free technique, getting rid of the demand for potentially hazardous disinfectants and minimizing the threat of harmful sanitation byproducts.

Unlike typical sanitation methods that rely on chemicals, UV sanitation utilizes ultraviolet light to destroy the DNA of microbes, rendering them unable to recreate and trigger infections. Unlike standard disinfection methods that depend on chemicals or heat, UV innovation does not leave any type of residue or modify the taste, appearance, or nutritional worth of the food. As modern technology enhances, we can anticipate to see much more cost-efficient and reliable UV disinfection systems being applied in go to website food handling plants, making certain that the food we take in is safe and cost-free from unsafe bacteria.

In conclusion, UV sanitation is an innovative technology that is changing sanitation practices in health care setups and food processing.

Report this page